TUFFSTAND: THE GORILLA ON THE RIGHT-OF-WAY

The DuraPlas TuffStand product line is designed to be the toughest, safest pipe stands in the oil and gas industry. These single injection molded products were developed utilizing patent pending designs that will provide the safety and efficiency the industry deserves. With the TuffStand you will:

- Save Time, Labor & Freight Costs

- Increase Safety

- Out-Perform traditional wood support Systems

-

2021 FINALIST! Pipeline & Gas Journal

Best Repair Technology Advancement

TUFFSTAND MODELS

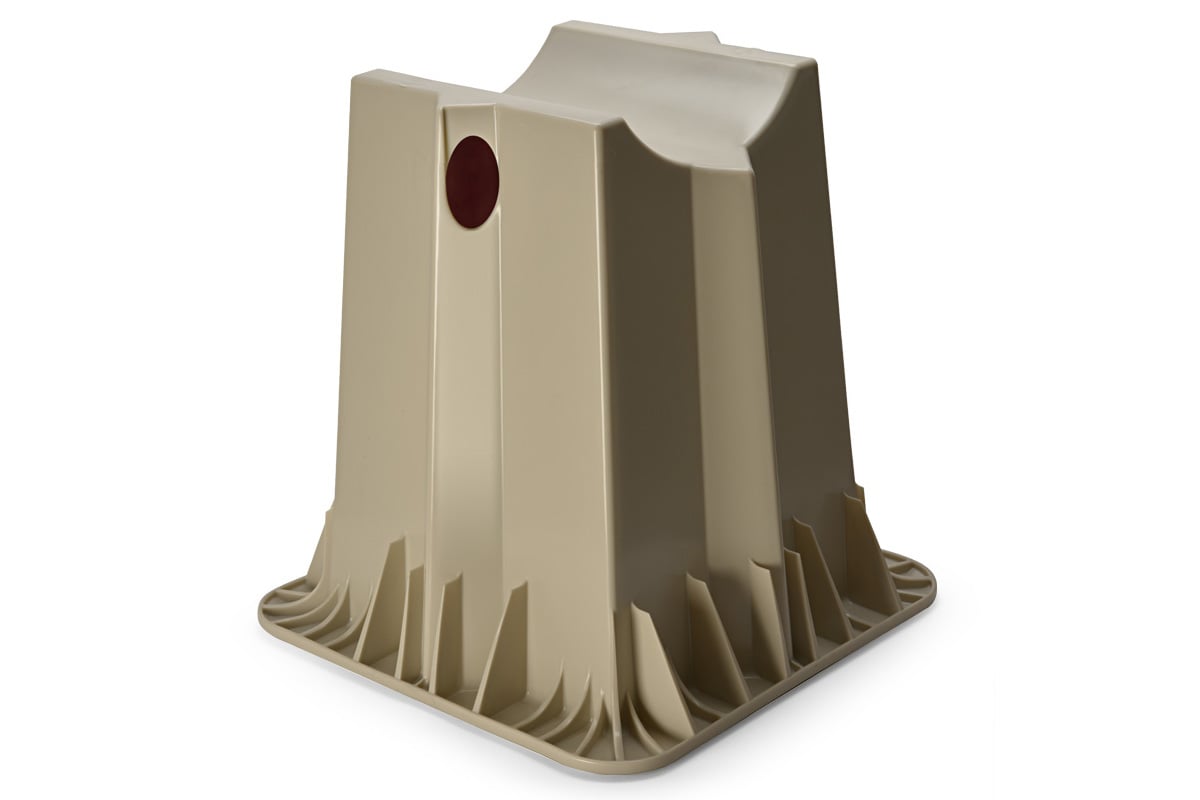

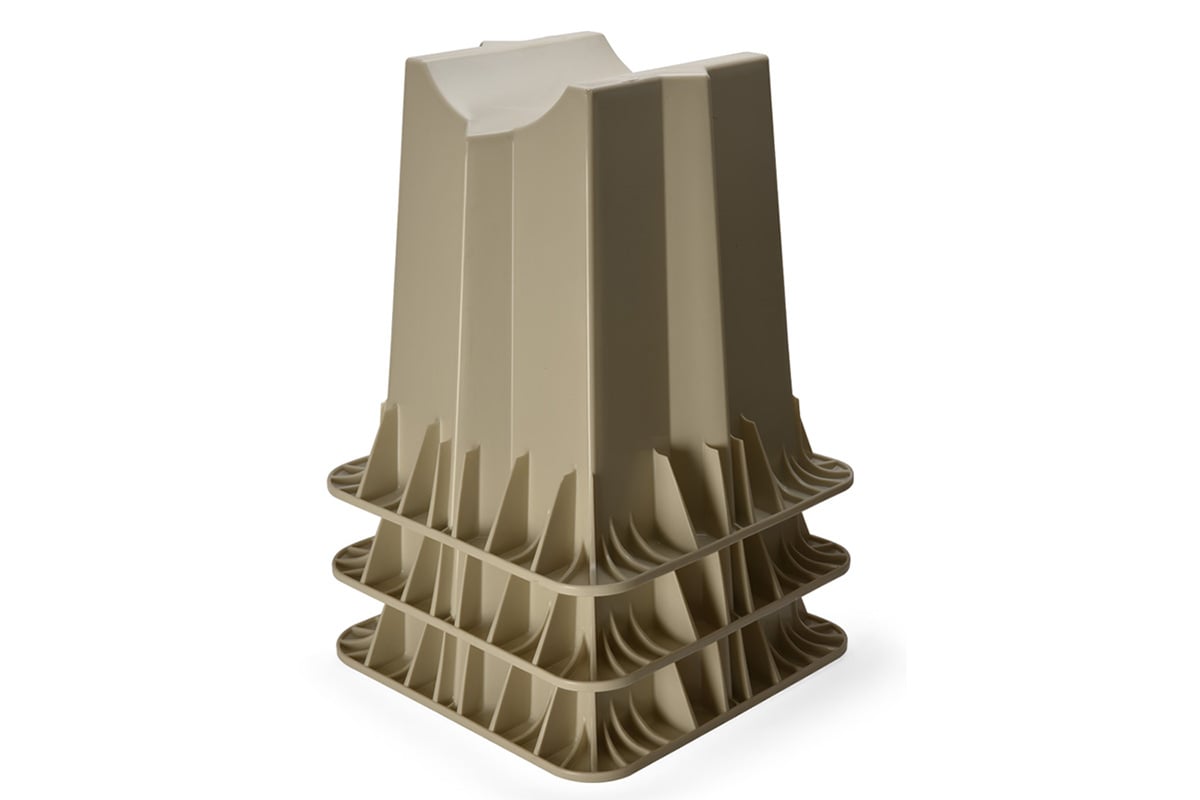

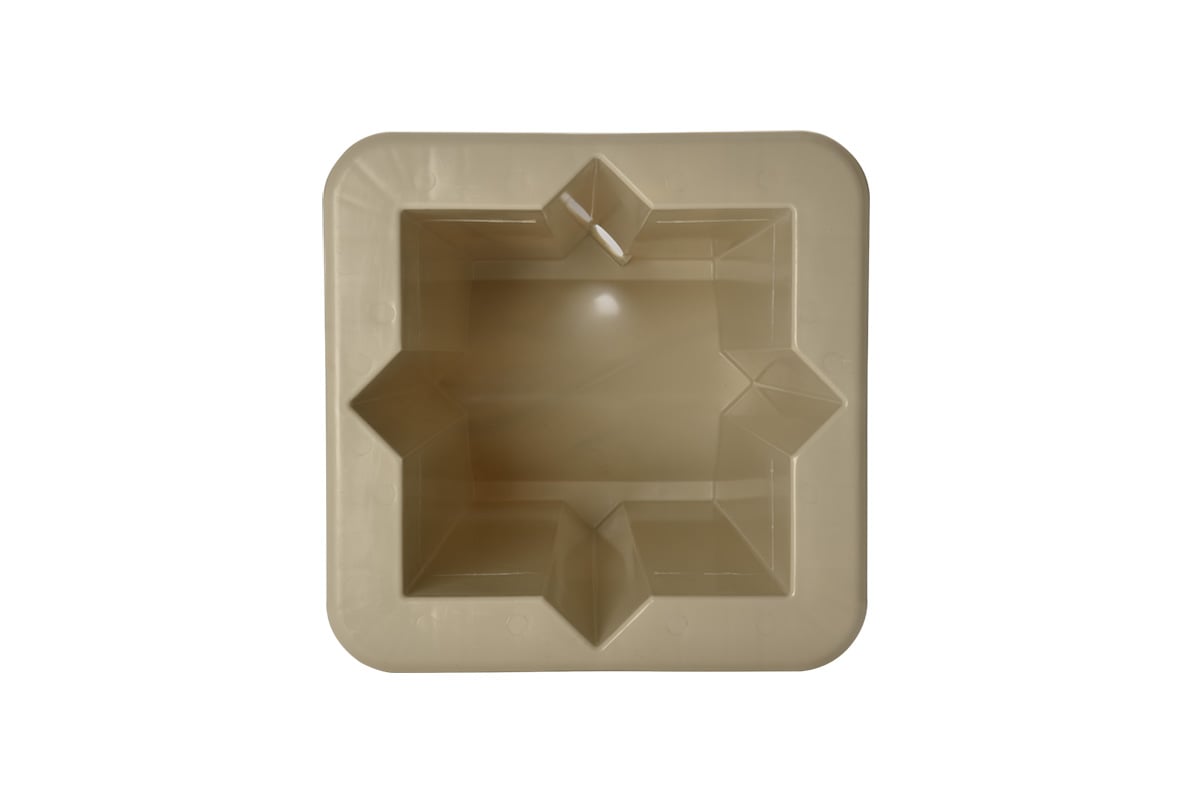

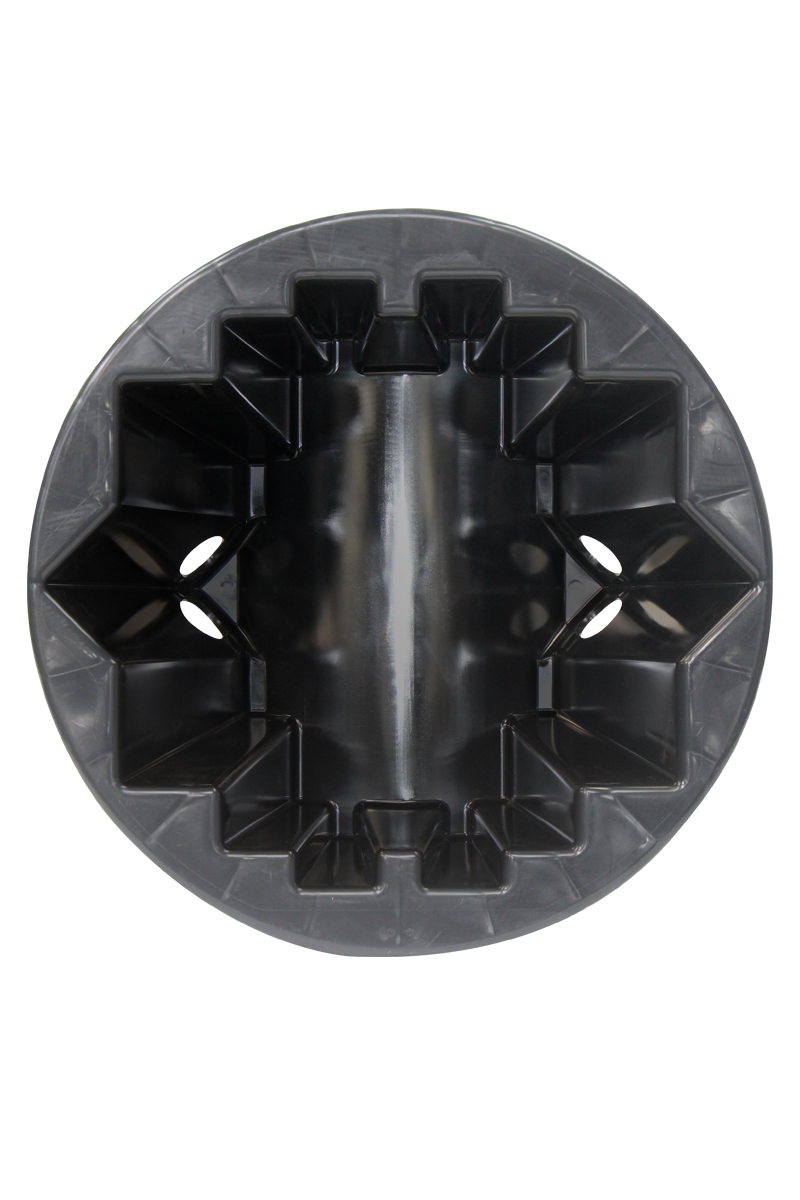

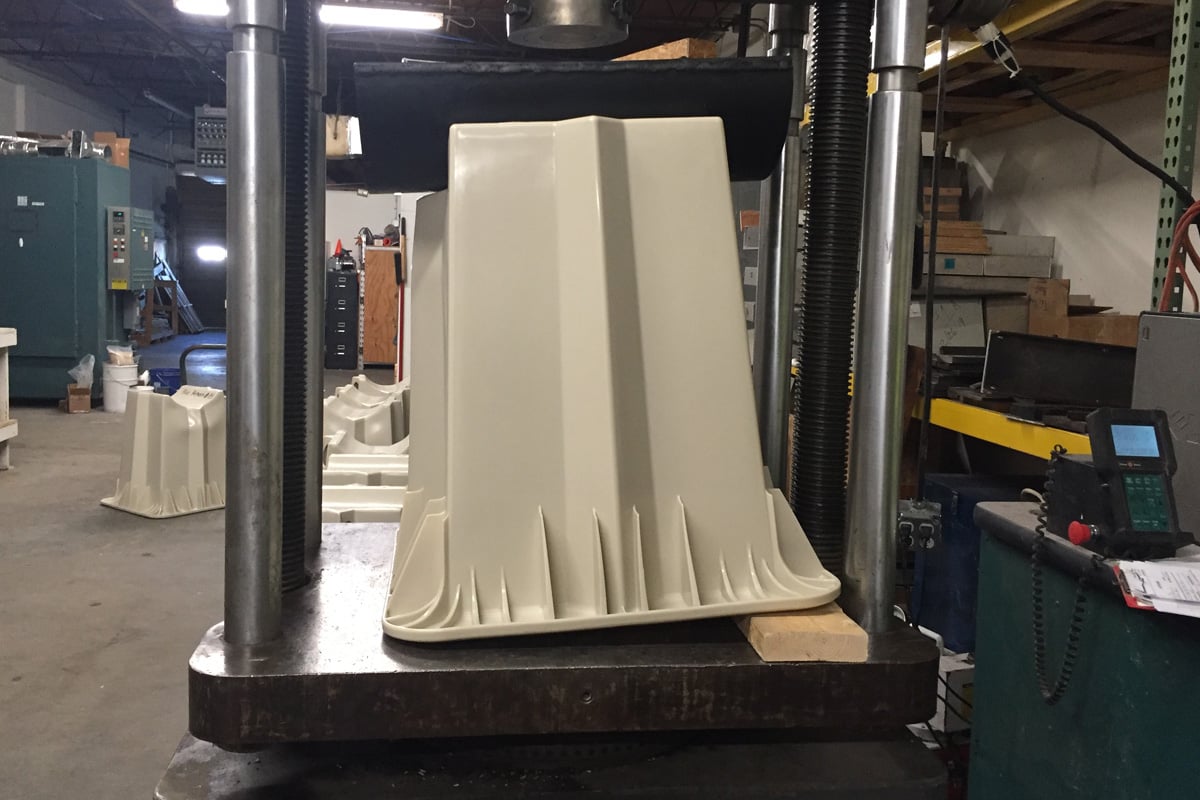

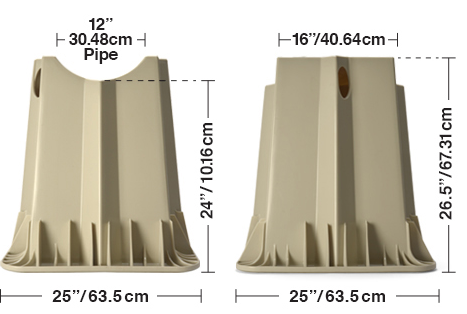

12" TUFFSTAND: TS12-ST TN

The DuraPlas 12″ TuffStand is designed to be the strongest, safest, and most durable 12″ pipe stand in the oil and gas industry. Utilizing a wide square base and angled side walls, the 12″ TuffStand can withstand the extreme conditions of any pipeline job using 2-12″ pipe. When developing this pipe stand, our goal was to create the absolute best product that provides the safety and efficiency the industry deserves. By replacing a pile of wood skids with the 12″ TuffStand, you are able to increase job efficiency and cut down on the labor costs associated with hauling and moving wood skids. And while wood skids are heavy and often cracked, wet, and rotten, our 12″ TuffStand weighs just 28.5lbs and is made with a high-density polyethylene resin. Make the switch and start using the 12″ TuffStand today!

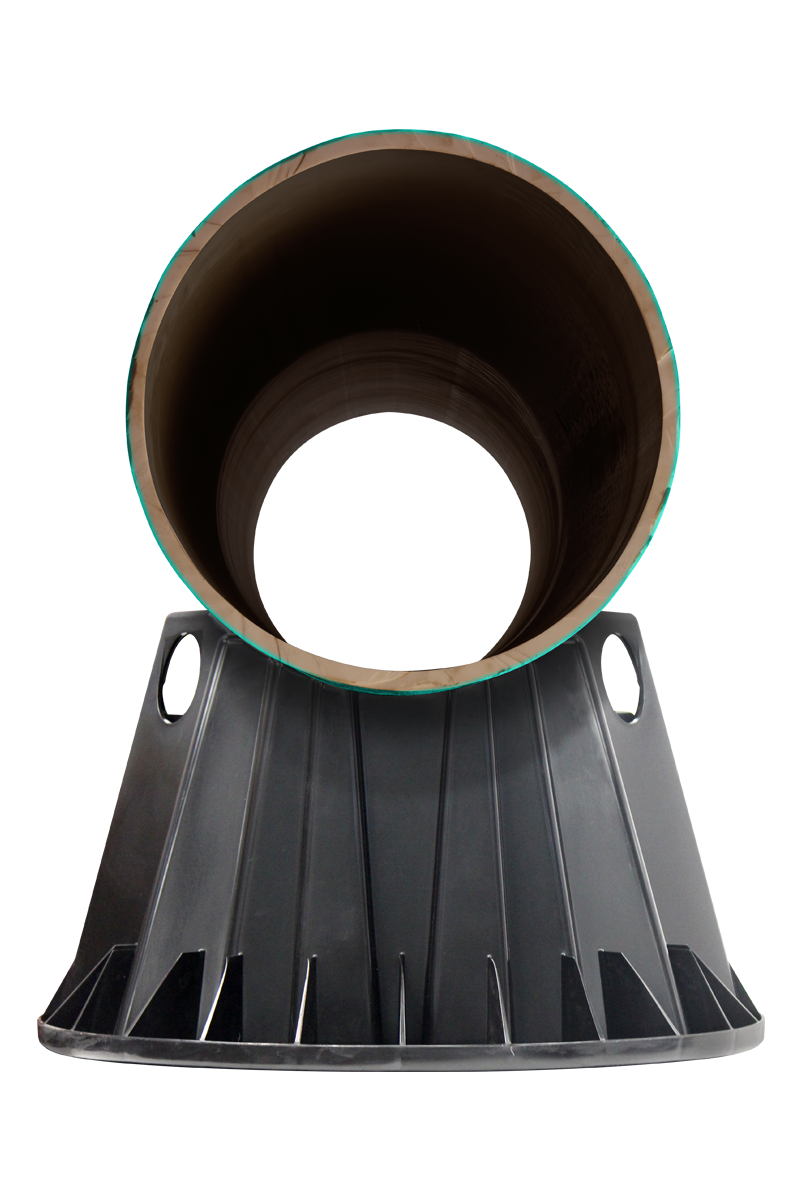

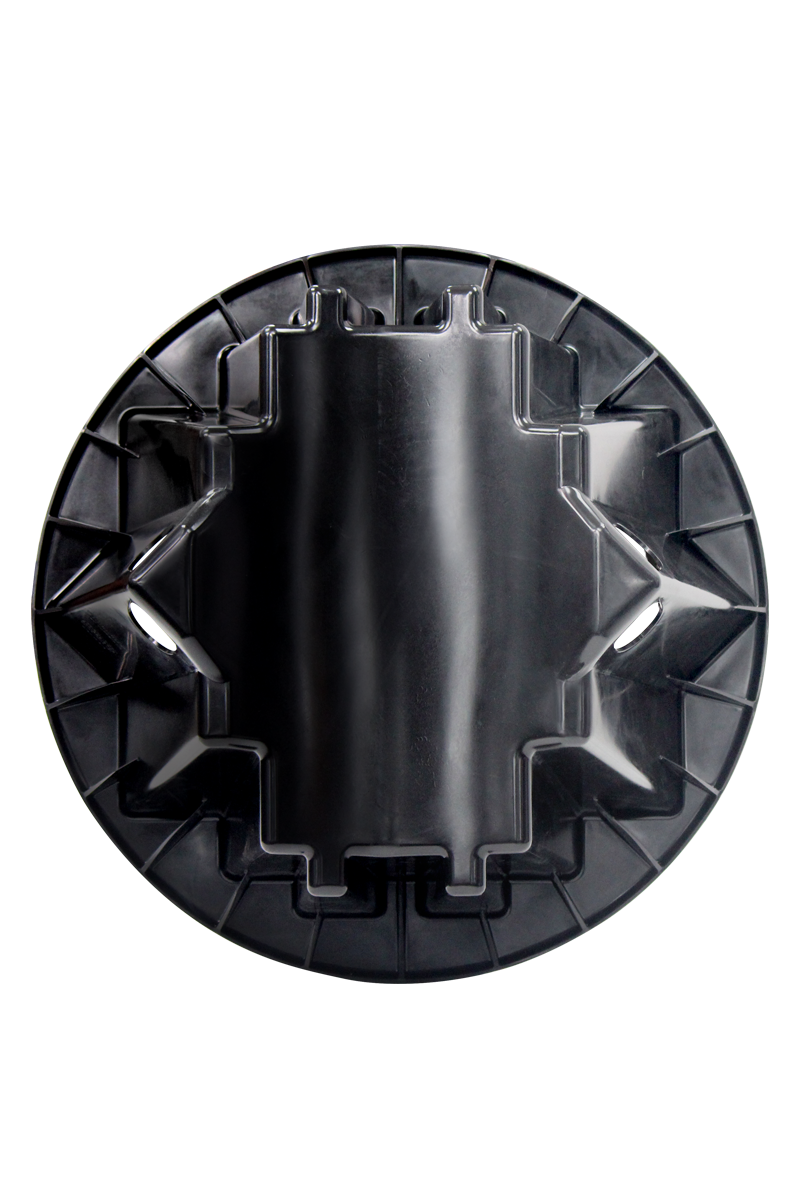

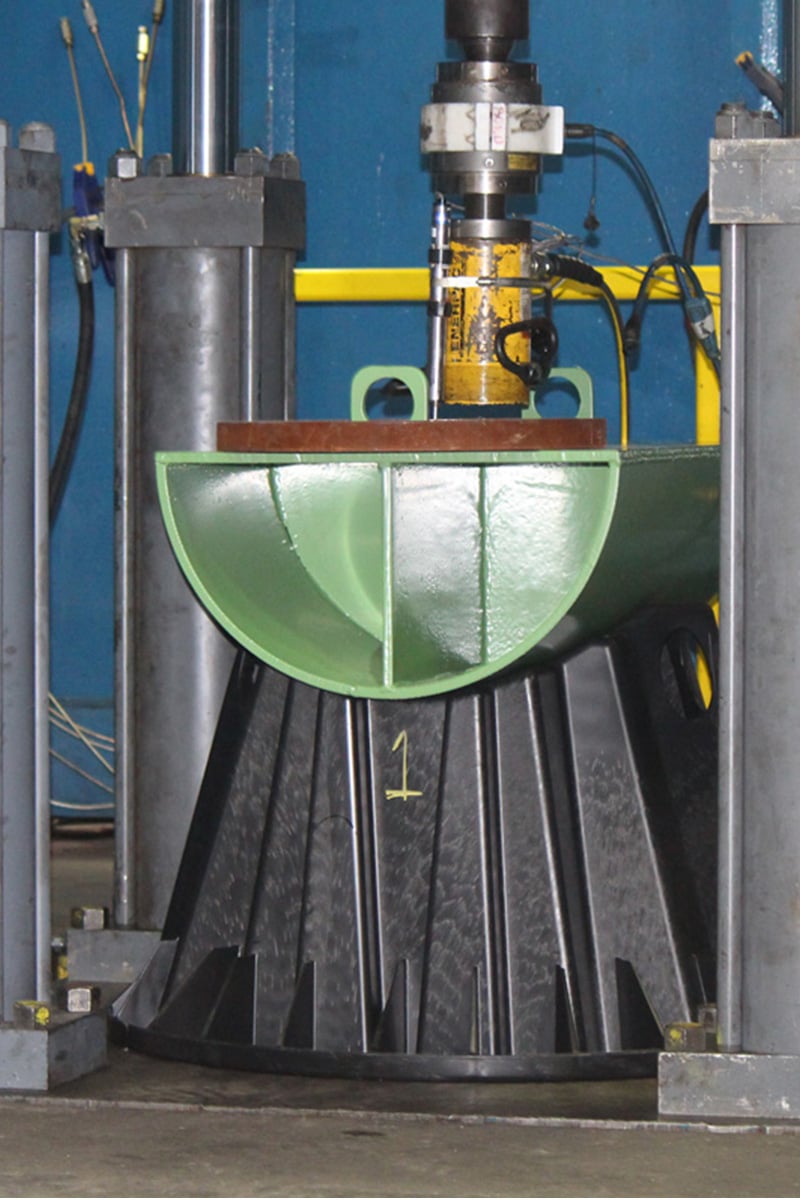

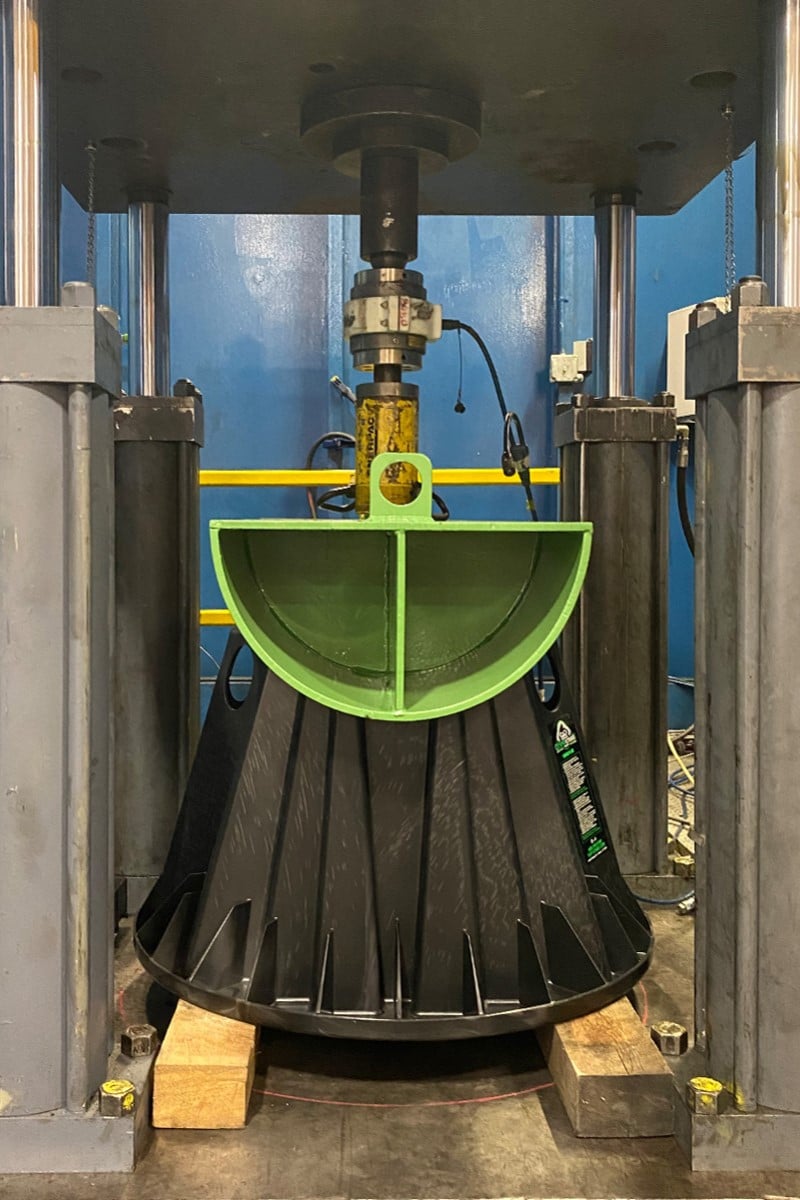

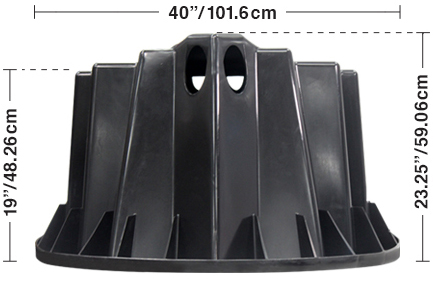

24” TUFFSTAND: TS24-ST BK

The 24” TuffStand is capable of handling up to 24” pipe diameters and has set the bar as the new industry standard. As the only pipe stand in the industry manufactured with Super-Tough Nylon Resin, the 24” TuffStand supported over 75,000 lbs* in a controlled testing facility! The first-of-its-kind design and top grade Super-Tough Nylon allow our 24″ TuffStand to carry a workload 3X more than any other plastic 24″ stand.

With the 24” TuffStand, you can tackle larger pipe projects while saving money on freight, labor, and time.

*Tests were completed in a controlled environment on flat surfaces under perfect conditions. *Do not exceed maximum load limit of 10,500 lbs.

| Technical Specifications | |||||

| Model | Base | Top | Saddle | Weight | Stands / Pallets |

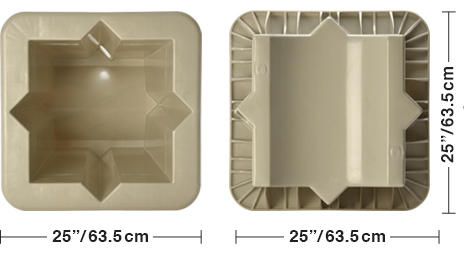

| TS12-ST TN (12" TuffStand) |

25" x 25" 63.5cm x 63.5cm |

16" x 16" 40.64cm x 40.64cm |

3" Deep 7.62cm Deep |

28.5 lbs 12.93 kg |

52 |

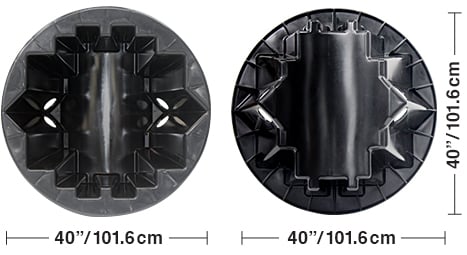

| TS24-ST BK (24" TuffStand) |

40" Diameter 101.6cm Diameter |

29" x 19" 73.66cm x 48.26cm |

4.25" Deep 10.8cm Deep |

33.5 lbs 15.2 kg |

12 |

Pro Tips

The experts at DuraPlas have put together some Pro Tips to help improve

your operation and get the most out of your equipment.

Resources

12" TuffStand: Use Instructions

IMPORTANT: Failure to follow these instructions can result in serious injuries or damages to the TuffStands.

Replace product if any physical defects are present such as cracking or discoloration. These stands are designed to absorb the weight of the pipe and give under an extreme load rather than crack. After the weight is removed, the pipe stand should regain its normal shape. Stands should be replaced if there is visible discoloration or cracking.

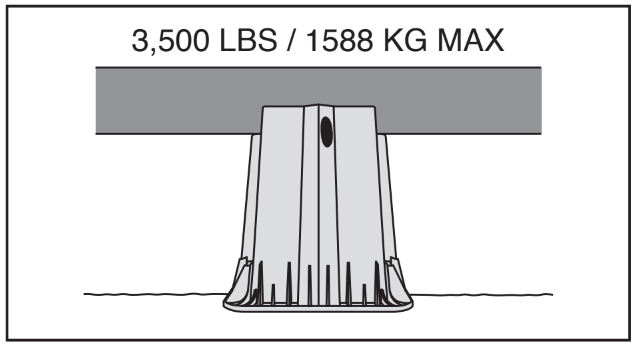

Load Limit: 3,500 lbs (1,588 kg)

Although our 12″ (30.5 cm) TuffStand was lab tested and held over 20,000 lbs (9,072 kg), the stands should never be overloaded. There are many factors involved on the job site that cannot be replicated in a controlled testing environment.

*The 12” TuffStand product is only rated for up to 3,500 lbs (1,588 kg)

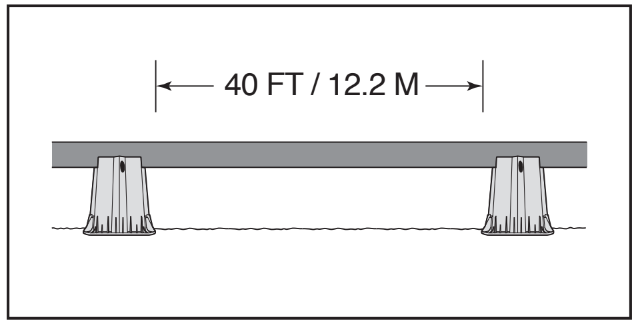

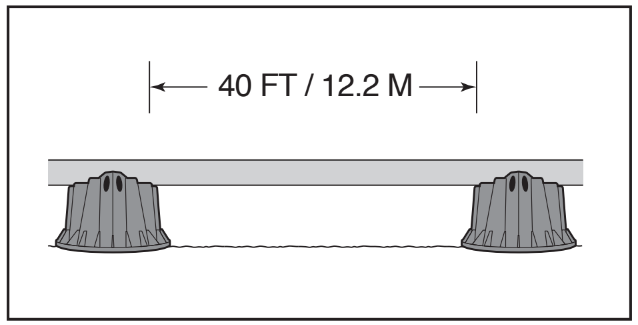

Suggested Spacing: Up to 40 Linear Feet (12.2 Meters)

The 12” TuffStand was designed and tested to handle “quad” lengths which is +/- 80 linear feet (24.4 m), however we still suggest a maximum of 40 feet (12.2 m) between spacings for overall safety.

*Ultimate spacing should be determined using pipe weight and should never exceed 3,500 lbs (1,588 kg))

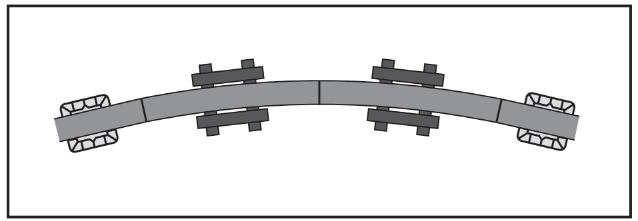

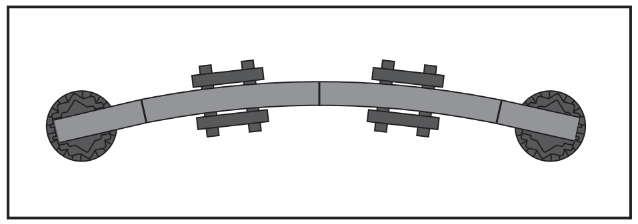

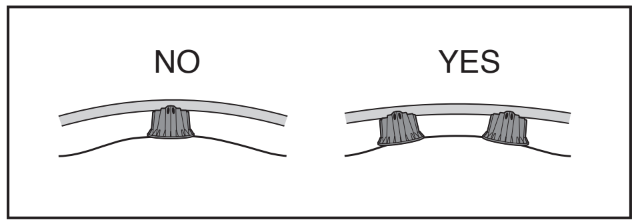

Do Not Use TuffStand on Bends

The TuffStand should not be used within a bend. Stands are acceptable for use before and after a bend.

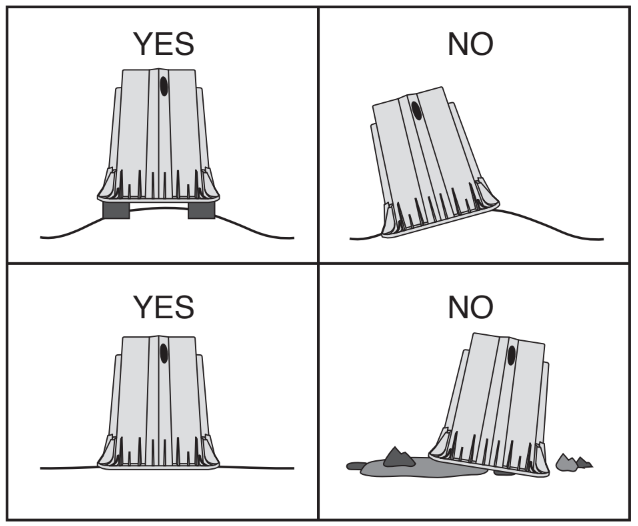

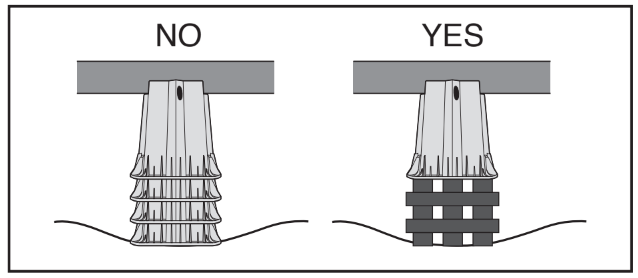

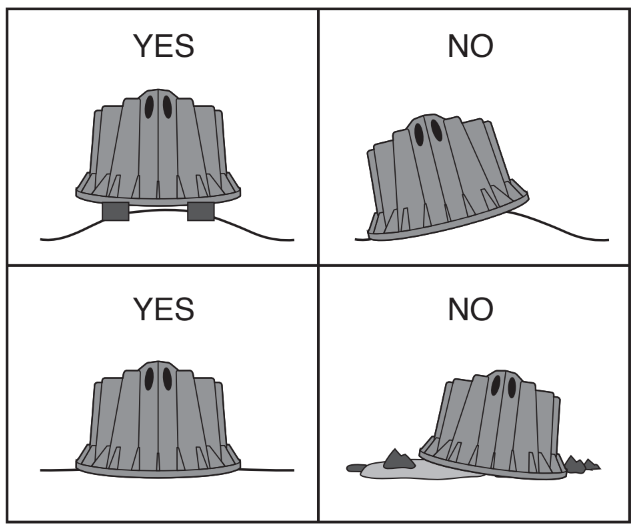

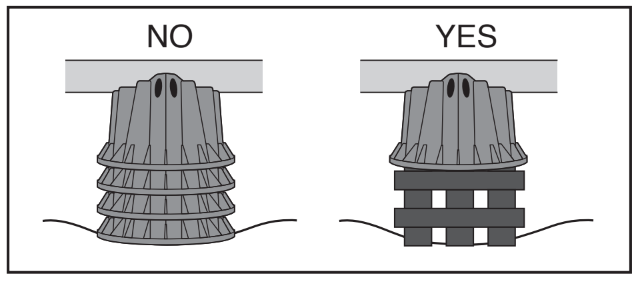

Use Only on Level Surfaces or Place Two (2) Wood Skids Underneath Pipe Stand

When working on uneven ground, the chances of the stand tipping over increases. Level the right-of-way or place the stand on two (2) evenly spaced wood skids.

The base of the stand should not be placed on large rocks or sharp objects. The base should be in full contact with the ground.

The maximum slope for the stand is not to exceed 10 degrees.

*Suggested: Skids run perpendicular to the pipe

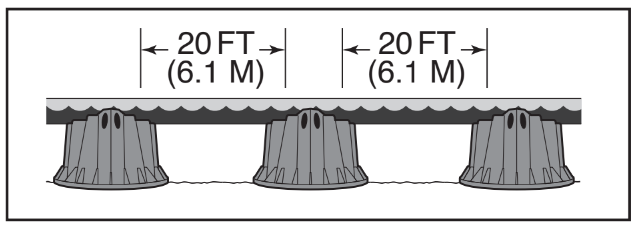

Double-up TuffStands When Hydrotesting

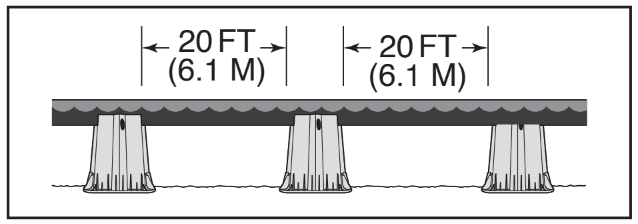

When hydrotesting, the water adds much more weight to the product. Hydrotesting is not recommended on the stands but in the event it needs to be done for bore sections, etc., it is necessary to utilize a 20 linear foot (6.1 m) spacing.

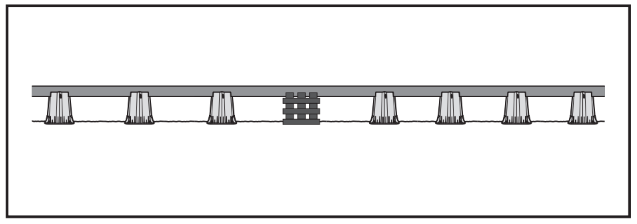

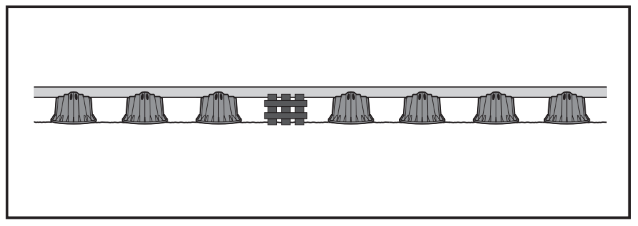

Place Skids/Crotch Every 7 to 10 TuffStands

Recommended to place a crotch every 7-10 stands to ensure the line does not tip over during handling/construction or in expansion / contraction that occurs with temperature changes. Skid sections should be a minimum of 6 skids in height to achieve 24″ (61 cm).

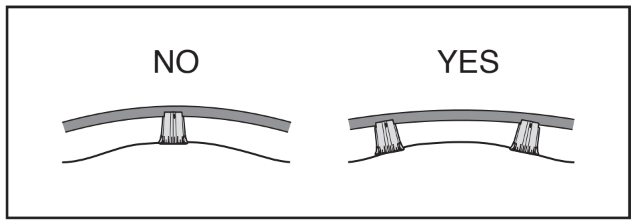

On a Hill or Overbend, Use Two (2) TuffStands

When placing a stand on top of an overbend/hill, the weight and force of the pipe is doubled. Disperse the weight by placing two (2) stands on either side of the top of the hill.

Do Not Stack Tuffstands to Gain Elevation

In order to gain elevation, place a few skids underneath and/or build a flat “platform” for a single stand to sit on top. When adding the weight of the pipe to a stack of stands, the stands will nest very tightly and will be difficult to separate.

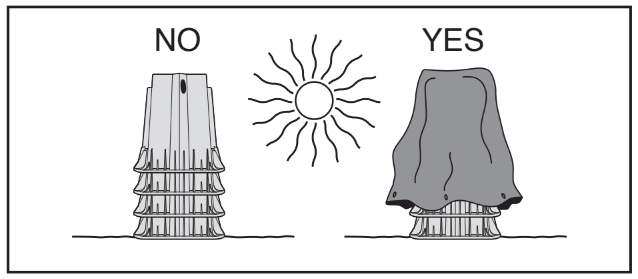

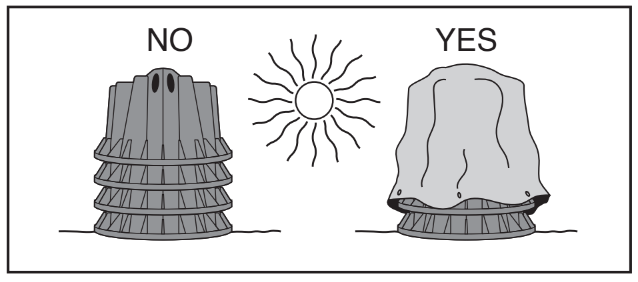

Cover/Tarp When Not in Use

Although our stands have UV protection, it is recommended to further protect the stands from sun damage which can cause the plastic to breakdown and weaken over time. To get the most out of our TuffStands, cover them when not in use.

24" TuffStand: Use Instructions

IMPORTANT: Failure to follow these instructions can result in serious injuries or damages to the TuffStands.

Replace product if any physical defects are present such as cracking or discoloration. These stands are designed to absorb the weight of the pipe and give under an extreme load rather than crack. After the weight is removed, the pipe stand should regain its normal shape. Stands should be replaced if there is visible discoloration or cracking.

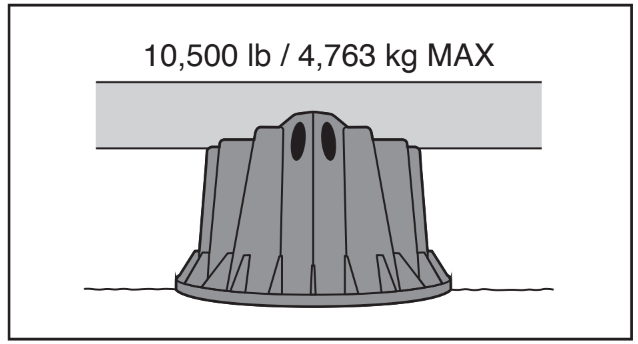

Load Limit: 10,500 lbs (4,763 kg)

Although our 24” (61 cm) TuffStand was lab tested and held over 75,000 lbs (34,019 kg), the stands should never be overloaded. There are many factors involved on the job site that cannot be replicated in a controlled testing environment.

*The 24” TuffStand product is only rated for up to 10,500 lbs (4,763 kg)

Suggested Spacing: Up to 40 Linear Feet (12.2 Meters)

The 24” (61 cm) TuffStand was designed and tested to handle “quad” lengths which is +/- 80 linear feet (24.4 m), however we still suggest a maximum of 40 feet (12.2 m) between spacings for overall safety.

*Ultimate spacing should be determined using pipe weight and should never exceed 10,500 lbs (4,763 kg)

Do Not Use TuffStand on Bends

The TuffStand should not be used within a bend. Stands are acceptable for use before and after a bend.

Use Only on Level Surfaces or Place Two (2) Wood Skids Underneath Pipe Stand

When working on uneven ground, the chances of the stand tipping over increases. Level the right-of-way or place the stand on two (2) evenly spaced wood skids.

The base of the stand should not be placed on large rocks or sharp objects. The base should be in full contact with the ground.

The maximum slope for the stand is not to exceed 10 degrees.

*Suggested: Skids run perpendicular to the pipe

Double-Up TuffStands when Hydrotesting

When hydrotesting, the water adds much more weight to the product. Hydrotesting is not recommended on the stands but in the event it needs to be done for bore sections, etc., it is necessary to utilize a 20 linear foot (6.1 m) spacing.

Place Skids/Crotch Every 7 to 10 TuffStands

Recommended to place a crotch every 7-10 stands to ensure the line does not tip over during handling/construction or in expansion / contraction that occurs with temperature changes. Skid sections should be a minimum of 5 skids in height to achieve 19″ (48.2 cm).

On a Hill or Overbend, Use Two (2) TuffStands

When placing a stand on top of an overbend/hill, the weight and force of the pipe is doubled. Disperse the weight by placing 2 stands on either side of the top of the hill.

Do Not Stack TuffStands to Gain Elevation

In order to gain elevation, place a few skids underneath and/or build a flat “platform” for a single stand to sit on top. When adding the weight of the pipe to a stack of stands, the stands will nest very tightly and will be difficult to separate.

Cover/Tarp When Not in Use

Although our stands have UV protection, it is recommended to further protect the stands from sun damage which can cause the plastic to breakdown and weaken over time. To get the most out of our TuffStands, cover them when not in use.